Precision Harvest Analytics. At the Edge.

Automated size and shape distribution for potatoes and sugar beets. Hardware-accelerated computer vision that syncs seamlessly to the cloud.

We work with these harvesters

Root Vision integrates with self-propelled and tractor-pulled harvesters from leading manufacturers, delivering real-time analytics regardless of equipment type.

From Field to Dashboard

Four stages. Fully automated. No operator intervention required.

Install

Ruggedized sensors mount directly on harvester conveyors.

IP67-rated housingConfigure

Select crop profile and market parameters.

Potato / Sugar BeetHarvest

Passive monitoring during standard field operations.

Zero downtimeEdge-to-Cloud

On-device AI processes video locally; results are transmitted instantly via cellular network.

4G/5G LTEBuilt for the Edge

Edge Computing

Heavy lifting happens on the harvester. Only lightweight data packets are sent, ensuring stability even in low-coverage areas.

Live Distribution

REAL-TIMEReal-time grading across all size categories.

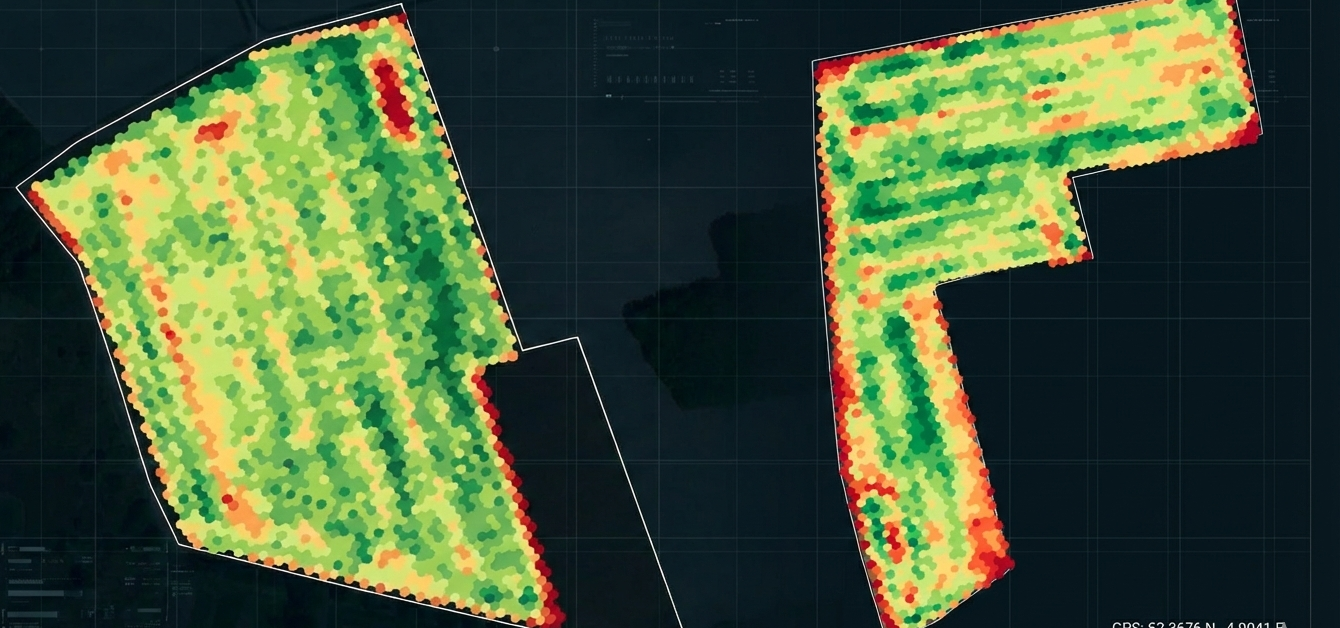

Size Mapping

Root Vision integrates with yield monitoring partner platforms to map size distribution with yield map.

API First

Raw JSON access and integration with existing Farm Management Information Systems (FMIS).

{

"session_id": "HRV-2024-0847",

"crop": "potato",

"distribution": {

"seed": 0.22,

"table": 0.54,

"processing": 0.24

},

"total_count": 14832,

"avg_diameter_mm": 48.3

}Why Root Vision

Different markets, different parameters. One system.

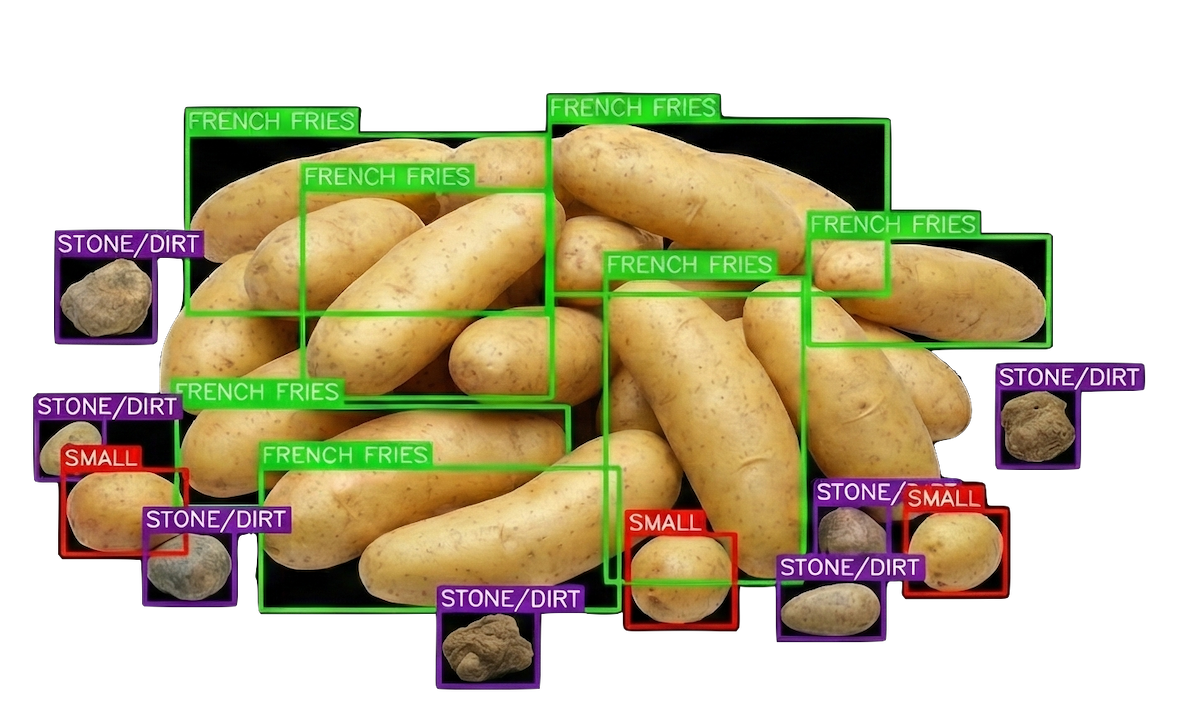

The French Fry Processor

Target specific length/width ratios to maximize contract fulfillment. Root Vision identifies potatoes that meet the exact dimensional criteria your processing partners require.

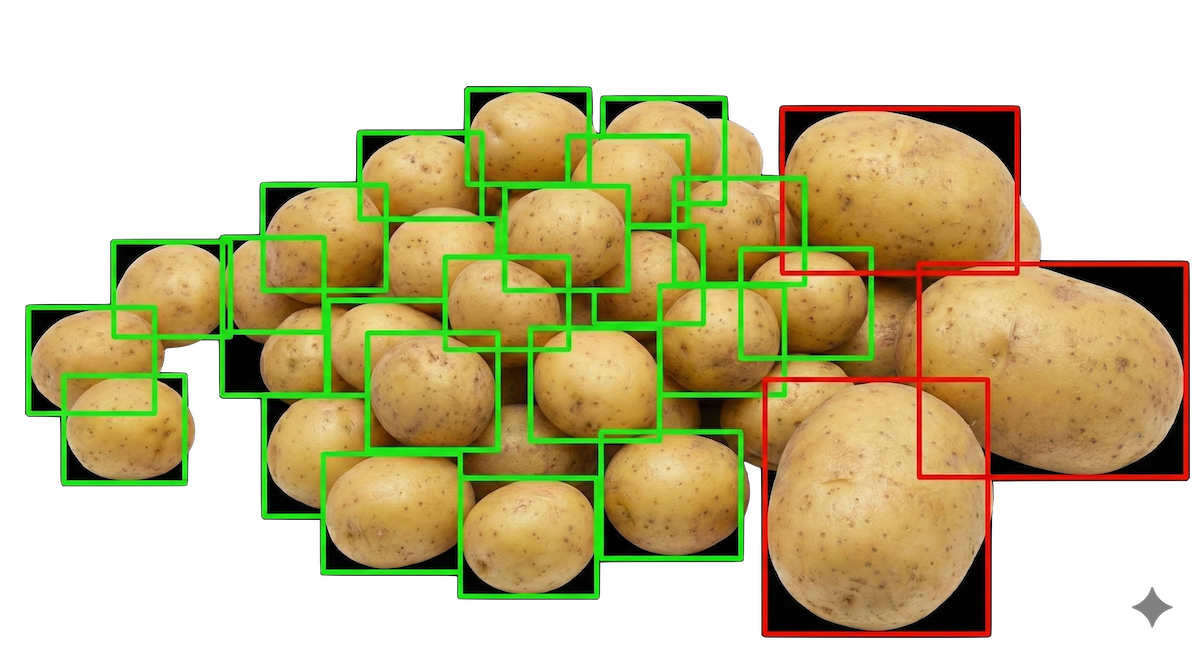

Seed Potatoes

Identify heavy concentrations of small tubers ideal for replanting. Automated sorting data enables precision seed stock management at scale.

Get in touch

Tell us about your harvesting setup. We'll get back to you within 24 hours.